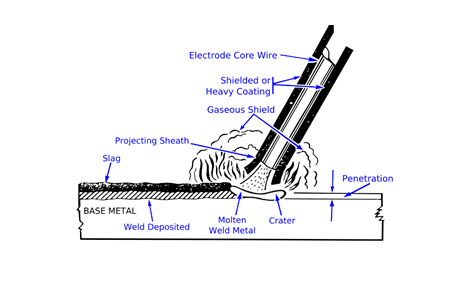

MMAW / SMAW

Shielded metal arc welding (SMAW), also known as manual metal arc welding (MMA or MMAW), flux shielded arc welding[1] or informally as stick welding, is a manual arc welding process that uses a consumable electrode covered with a flux to lay the weld. An electric current, in the form of either AC or DC from a welding power supply, is used to form an electric arc between the electrode and the metals to be joined.

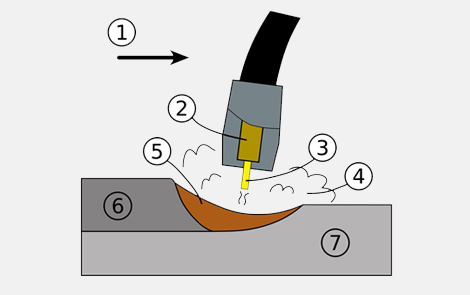

TIG / GTAW

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non- consumable tungsten electrode to produce the weld. The weld area and electrode is protected from oxidation or other atmospheric contamination by an inert shielding gas (argon or helium), and a filler metal is normally used.

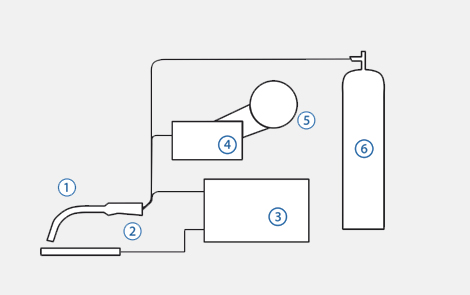

MIG / GMAW

Gas metal arc welding (GMAW) or metal inert gas (MIG) welding or metal active gas (MAG) welding, is a welding process in which an electric arc forms between a consumable wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to melt and join. Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from contaminants in the air. The process can be semi-automatic or automatic. A constant voltage, direct current power source is most commonly used with GMAW.

MMAW / SMAW Transformer

Salient Features

- Higher metal recovery ensures lower consumption of electrodes.

- Superior dynamic characteristics gives soft and smooth arc, minimum spatter.

- Robust and compact construction ability to withstand rough handling at sites.

ESAB Model

- TRANSWELD 400

- THH630

- XPERT 400

MMAW / SMAW Diode

- LHJ425

- LHJ750

ESAB Model

Salient Features

- The rectifier has an option to fix ESAB digital V/A meter for showing the welding voltage and current.

- Fan cooled three phase rectifier connected to a three phase power.

MMAW / SMAW Transformer

- True, vertical welding current characteristics with higher open circuit voltage.

- Immunity from AC input voltage fluctuation, with

- built-in overload and thermal cut-out protections.

- Stable arc with regular droplet transfer and elimination of spatter generation.

- Hot start facilities for easy arc striking.

- Effective prevention of electrode freezing.

- Single range current control with remote control facilities.

- Excellent reliability with high performance suitable for outdoor, onsite use.

- Ideal for precise TIG welding with necessary

- accessories.

ESAB Model

- SSR400

- SSR600

MMAW / SMAW INVERTER

Salient Features

- Robust and Powerful

- MMA & TIG Welding Process

- Voltage Reduction Device – VRD

- Energy Efficient

- Safety and Reliability

- Light weight

- Adjustable hot start & Arc Force

- Wide mains voltage tolerance

- Generator Complaint

- BUDDY ARC 200

- ARC 250

- BUDDY ARC 400

- ARC 630i

- LHJ750

ESAB Model

TIG / GTAW Thristor

ESAB Model

- SSR400

- SSR600

Welders Jacket

Welding Jacket LW

Welding Apron

Welding Sleeve

Leg Guard

A- 20

Warrior Tech 9-13

Eco Arc ||

Hand Shield Armour

Filter Lens

Eco Air

Warrior Tech 9-13 Helmet Yellow For Air

Eco Smoke

Eco Amber

Eco Clear