REMAGRIP 50 AND 60

Fields of application and product advantages:

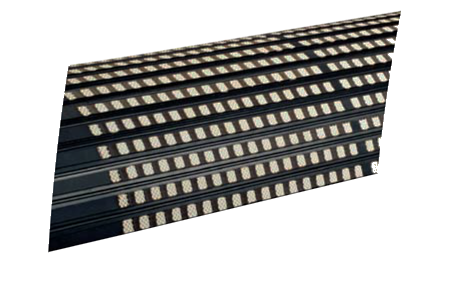

- Grooved rubber lagging for drive pulleys

- Avoidance of material build-up with positive in-fluence on belt tracking

- Reduced slippage between belt and pulley through increased coefficient of friction

- Evacuation of moisture and dirt

- Protects pulleys from wear and corrosion

- Pulley lagging for low to medium-tension fabric belts

REMAGRIP 65 AND 70

Fields of application and product advantages:

- Grooved rubber lagging for drive pulleys

- Avoidance of material build-up with positive influence on belt tracking

- Reduced slippage between belt and pulley through increased coefficient of friction

- Evacuation of moisture and dirt

- Protects the pulleys from wear and corrosion

- Long belt conveyors (REMAGRIP 70)

- Large pulley diameters (REMAGRIP 70)

- For high-tension fabric belts and medium to high-tension steel-cord belts (REMAGRIP 70)

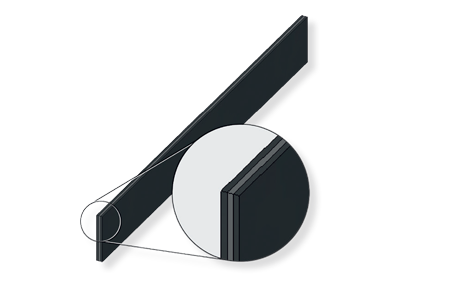

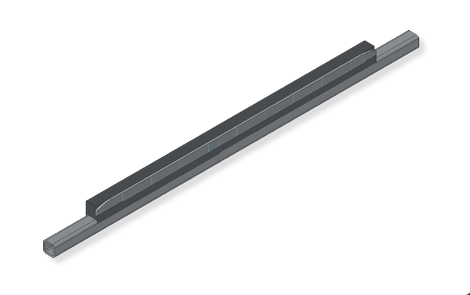

Further advantages REMAGRIP 70/CN-SL (strip lagging):

- Significantly improved evacuation of water through additional horizontal grooves

- Preparation of the strips in the workshop, in the warehouse or on site

- Can be trimmed precisely with the REMA TIP TOP rubber cutting machine MODEL 32

- Easy application, even to pulleys in situ

For pulleys subject to high stress

Ceramic material is suitable for pulley lagging, thanks chiefly to its specific properties of extremely high wear resistance provi- ded by aluminium oxide (Al2O3). It replaces traditional materials, because it provides higher profitability by considerably increa- sing the service life and the efficiency of pulley laggings.

3 REMACLEAN BELT CLEANING SYSTEMS REMA TIP TOP

Fields of application and product advantages:

- Grooved rubber lagging for drive pulleys

- Avoidance of material build-up with positive influence on belt tracking

- Reduced slippage between belt and pulley through increased coefficient of friction

- Evacuation of moisture and dirt

- Protects the pulleys from wear and corrosion

- Long belt conveyors (REMAGRIP 70)

- Large pulley diameters (REMAGRIP 70)

- For high-tension fabric belts and medium to high-tension steel-cord belts (REMAGRIP 70)

Further advantages REMAGRIP 70/CN-SL (strip lagging):

- Significantly improved evacuation of water through additional horizontal grooves

- Preparation of the strips in the workshop, in the warehouse or on site

- Can be trimmed precisely with the REMA TIP TOP rubber cutting machine MODEL 32

- Easy application, even to pulleys in situ

Scraper Rubber

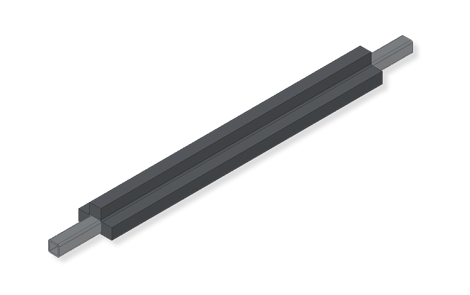

REMACLEAN 60 and 70

Due to its excellent abrasion-resistance and high elasticity, our special rubber materials REMACLEAN 60 and REMACLEAN 70 are perfectly suitable and achieve significantly longer service life compared to conventional rubber materials.The scraper rubber is mounted on the system’s existing scraper system and when new may protrude from the bracket by up to its own thickness.

Remaclean Cab

Fields of application and product advantages:

REMACLEAN CAB consists of three layers with different Shore hardnesses: two hard outer layers surround a soft core. This combination allows intensive and yet protective conveyor belt cleaning. At the same pressure against the conveyor belt, the cleaning effect of REMACLEAN CAB is approximately 20 % better than standard qualities. Service life is often several times longer than that of conventional scraper rubber materials. REMACLEAN CAB is mounted on the existing scraping system of the equipment and when new can protrude from the bracket by more than one and a half times its own thickness.

Scraper Rubber

Remaclean KWA

REMA TIP TOP offers a wide range of scraper bars for cleaning of conveyor belt top covers on the return side of the conveyor. Scraper barsmade of rubber, polyurethane, rubber-ceramic and rubber-metal are available.

Benefits and features:

- Three scraper bars which can be used one after the other

- Belt-friendly scraper with good cleaning efficiency

- Long service life due to highly abrasion resistant rubber material

- Cost-effective due to excellent price-performance ratio

- Installation is recommended with REMA TIP TOP tension units INNOVATION, PRECISION or STANDARD

- For belt speeds up to 3.5 m/s

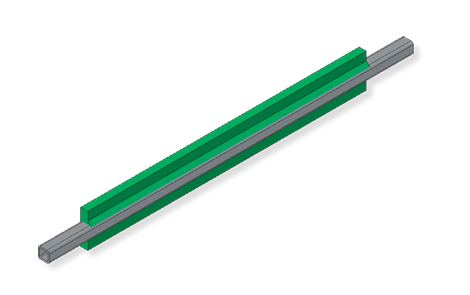

Remacleam Pur

Benefits and features:

- Two scraper bars which can be used one after the other

- Long service life of REMATHAN polyurethane (90 ±5 Shore A)

- Oil and grease resistant

- For belt widths 500 - 1600 mm

- Installation is recommended with REMA TIP TOP tension units INNOVATION, PRECISION or STANDARD

- Suitable for use with mechanical fasteners

- Suitable for shuttle belt operation in combination with tension unit INNOVATION

- For belt speeds up to 3.5 m/s

REMACLEAN C

Benefits and features:

- Highly wear resistant through AL2O3 ceramic material

- Flexibility through ceramic material embedded in rubber

- Belt friendly cleaning due to rounded outer ceramic elements

- For belt widths 400 - 1600 mm

- Installation is recommended with REMA TIP TOP tension units INNOVATION, PRECISION or STANDARD

- Do not use with quartz-containing bulk material

- For belt speeds up to 3.5 m/s

REMACLEAN M

Benefits and features:

- Highly wear-resistant through tungsten carbide insert

- Permanently vulcanised into an elastic rubber base

- Belt friendly cleaning through rounded outer tungsten carbide blades

- For belt widths 400 - 1600 mm

- Installation is recommended with REMA TIP TOP tension units INNOVATION, PRECISION or STANDARD

- For belt speeds up to 3.5 m/