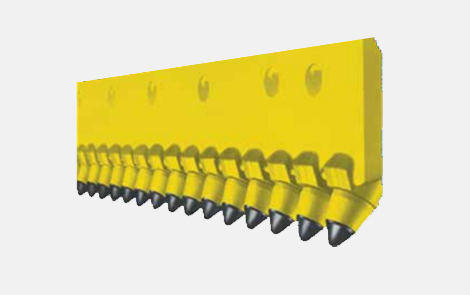

Scarifier Blades

- Penetrates hard-packed gravel and frozen surfaces easily with less down pressure and horsepower.

- Eliminates “washboarding” and pot holes with fewer passes than standard blades.

- Decreases the number of passes necessary to properly maintain a road surface.

- Features replaceable, rotating, self-sharpening, solid carbide-tipped cutting tools that wear uniformly and last longer than all-steel blades.

- Reduces machine and operator downtime significantly by eliminating the need to replace entire blade sections and instead, allowing for the quick change of individual tools.

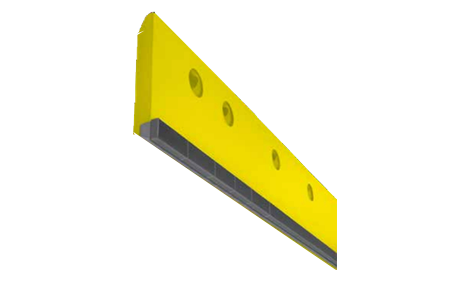

Dual-Carbide Blades

- Provides maximum wear resistance.

- Features two tungsten carbide inserts, specifically designed for high-abrasion and low-impact applications.

- Outlasts imbedded carbide granule-style blades.

- Offers the longest lasting blade life span in the industry.

- Reduces costs associated with replacement part inventory, downtime, labor, and overall operations.

- Resists “crowning” and maintains a straighter cutting edge throughout the life of the blade.

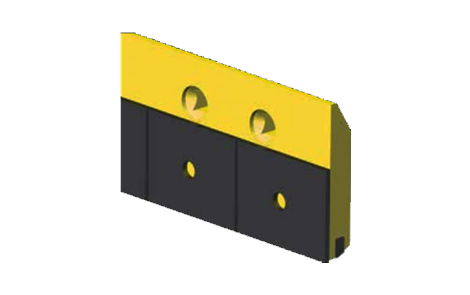

I.C.E.™/KenCoat™ Blades

- Combines durable, individually mounted bullet-shaped inserts with wear-resistant carbide granules embedded in a tough, abrasion-resistant, steel-weld material in one blade.

- Features optimal levels of blade wear, impact, and fracture resistance.

- Designed specifically for maximum performance and blade longevity.

- Performs effectively in snow removal operations on roads with embedded lane markers and rumble strips.

- Withstands high-speed plowing over excessive joints, major cracks, and uneven road surfaces.

KenCoat™ Blades

- Economical choices for moderate-impact applications.

- Resists wear from down pressure.

- Provides wear life 3–5x greater than standard carbide blades.

- Features wear-resistant carbide granules embedded in an abrasion-resistant, steel-weld material that offers better protection of the solid carbide insert in the blade.

- Available in both 1" (25mm) and 1.50" (38mm) wide KenCoat protection.

Armored Blades

- Economical choices for higher-impact applications.

- Offers wear life 3–5x greater than standard carbide blades.

- Protects carbide insert by reinforcing the mild steel face with a securely welded hardened-steel plate.

- Available in 3ft (914mm), 4ft (1219mm), and 5ft (1524mm) lengths.

Grader Blades for Plowing Snow

- Offers unparalleled combination of fracture and wear resistance.

- Our brazing expertise ensures that inserts stay firmly in place, without residual stress, resulting in a more durable blade.

- Available in an unmatched variety of styles and sizes — each backed by the road maintenance industry’s best quality assurance program.

- Sold in combinations of 3ft (914mm) and 4ft (1219mm) lengths for more versatility, safety, and ease of use.

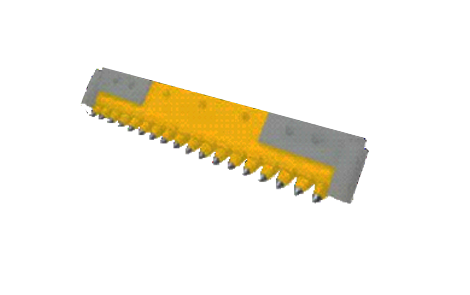

Scarifier Blades

Carbide-Tipped Cutting Tools, Blocks, and Accessories for Scarifier Blade Systems

Kennametal’s exclusive tungsten carbide-tipped cutting tools outlast all steel blades. Featuring rotating, self-sharpening cutting tools for more uniform wear and longer tool life, Kennametal blades provide exceptional cutting action in demanding, tough surfaces, including hard-packed gravel roads and frozen ground. Blades maintain an even cutting height by enabling cutting tools to be rotated from position to position. This significantly reduces machine and operator downtime by enabling operators to individually change worn cutting tools without using special tools, and without replacing entire blade sections and bolts — within a matter of minutes.

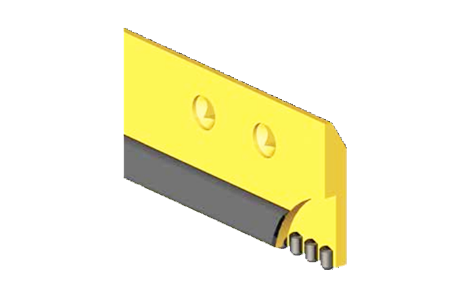

Cover Blades

Kennametal’s optional cover blades provide exceptional wear resistance and superior protection of the main blade body. We recommend using our wear- resistant steel cover blades when the scarifier system is operating in extremely abrasive conditions or when carrying heavy debris loads on the moldboard. The new, redesigned cover blade features an improved design that better protects the blocks and welds. Made of more wear-resistant steel and thicker than our previous models, these new cover blades attach easily through existing bolt holes on the blade using bolts that are .750" (19mm) longer than those used to attach the scarifier blade to the moldboard. Cover blade sections can be changed without changing the entire scarifier blade.

End Protectors

Kennametal carbide end protectors for scarifier blades feature a heavy-duty design and tough steel supports of the end protectors that resist breakage and bending in any road application. Our end protectors feature KenCast™ composite material that combines the wear resistance of Kennametal’s exclusive tungsten carbide with the ductility of air-hardening steel.

Dual Carbide Insert grader blades:

Kennametal’s Improved Dual Carbide Insert grader blades provide exceptional wear resistance to substantially reduce your replacement part inventory cost. Unlike high carbon, through-hardened or flame hardened steel blades, Kennametal’s patented dual carbide blade design stays straight,maintains a sharp,clean cutting edge, and stops crowning. World’s longest lasting blades have lasted for more than 4000 hours on Road Projects and more than 1000 hours in Mining Projects